Pneuconveyor systems & Engineers

EXPERIENCE IN MOTION

CUTOMER SUPPORT & SALES +91-8169813211 / 8169820763 +91-8169813211

INQUIRY NOW DOMESTIC – info@pneuconveyors.com INTERNATIONAL – exports@pneuconveyors.com

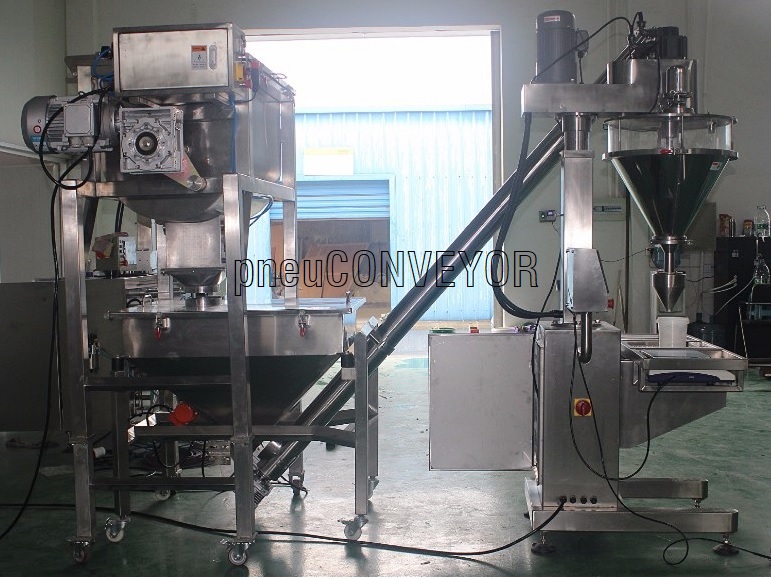

SCREW CONVEYOR

Description:

Screw Conveyor is a general type conveyor. It’s mainly used for conveying granule, powder and compound material. Two models as your choice: – Horizontal Screw Conveyor and Inclined Screw Conveyor. According to customer’s different requirements and industry, we can do special design for your company.

This machine is mainly used in conveying powder, particles of ascension, suitable for pharmaceutical, chemical, food and other industries, or with tablet compression machine hopper charging, sachet filling machine hopper charging, fully automatic, semi-automatic of injected powder packaging machine, form linkage, reduce the intensity of production operation and ensure accuracy of packaging, as a corollary equipment of choice. Compared with other transportation equipment, screw conveyor with the machine section size small, reliable sealing performance is good, smooth operation, screw and feeding tube adopts new structure of subsection and demountable facilitate transport clean and safe operation, convenient maintenance, etc.

Working Principle:

pneuCONVEYOR – series screw-driver feeder adopts one screw for feeding. Once the Power switch is opened, the screw begins to rotate and feed, so that material can be lifted up to the material outlet. The machine will stop working automatically when the level-sensing the device indicates that material is full, and starts working again after several minutes later when the material level decreases. (The delay time is depended on your choice)

The screw conveyor has many advantages over other types of bulk material handling equipment. Some of the advantages are:

- Screw conveyors are capable of handling a great variety of bulk materials from sluggish to free-flowing.

- Screw conveyors can have multiple inlet and discharge points. Bulk materials can be conveyed and distributed to various locations as required. Slide gates or valves can be added to control the flow into and out of a screw conveyor.

- When a screw conveyor is used as a metering device, it is considered a screw feeder. Screw feeders are used to initiate a material process by metering product from a bin or hopper.

- Screw conveyors are very compact and adaptable to congested locations. Screw conveyors do not have a return similar to a belt or drag conveyor.

- Screw conveyors are totally enclosed to contain the product and prevent spillage. Screw conveyors can be utilized in the horizontal, vertical or any inclined position depending upon the characteristics of the product being conveyed.

- Screw conveyors can be used for mixing various products together and for breaking up large lumps.

- Screw conveyors can be designed without a center pipe. This type of conveyor is called a shaft less screw conveyor and is designed for conveying wet, sticky, sluggish products such as industrial sledges and bio solids.

- Screw conveyors can be used to cool, heat or dry products in transit. Depending on the heat transfer requirements, a screw conveyor can be jacketed, or a hollow-flight design utilized to provide the necessary heat transfer for the application.

- Screw conveyors can be designed to be vapor-tight or hold an internal pressure. This is very important when conveying toxic or hazardous products such as those in the chemical industry.

- Screw conveyors can provide an air lock between upstream and downstream equipment.

- This product is widely used in Pharmaceuticals, Chemical, Bulk Drug, Food, Milk powder feed, Plastic, Paint, Pesticides, Cement and building materials.

Technical Specifications :-

Model | SC100 | SC120 | SC140 | SC160 | SC200 | SC250 | SC300 | SC400 | ||

Diameter of screw (mm) | 90 | 115 | 135 | 163 | 185 | 237 | 285 | 362 | ||

Rotary speed of main axis (r/min) | 300 | 300 | 300 | 308 | 260 | 200 | 170 | 170 | ||

Diameter of main case(mm) | 108 | 133 | 159 | 194 | 219 | 273 | 325 | 402 | ||

Max capacity (t/h) | 7 | 10 | 15 | 25 | 40 | 60 | 90 | 120 | ||

Max Length of conveying length L (m) | 8 | 10 | 12 | 15 | 18 | 25 | 25 | 25 | ||

Working angle (degree) | 0°~60° | 0°~60° | 0°~60° | 0°~60° | 0°~60° | 0°~60° | 0°~60° | 0°~60° | ||

Motor | model | L ≤ 5M | SC-100 | SC120 | SC-140 | SC160 | SC200 | SC250 | SC300 | SC400 |

Power(kw) | 1.1 | 2.2 | 3 | 5.5 | 7.5 | 11 | 18.5 | 18.5 | ||

model | L ≥ 5M | SC100 | SC-120 | SC-140 | SC160 | SC200 | SC250 | SC300 | SC400 | |

Power( kw) | 2.2 | 3 | 4 | 7.5 | 11 | 15 | 22 | 22 | ||

Note:- All technical parameter above is just for your reference, screw conveyor in our company can be customized by your special requirement, e.g. wear resistant, corrosion resisting, heat retaining.

Visit Us

ADDRESS: Pneuconveyor systems & engineers Unit: 23&24, Padmini Industrial Complex, Purna-Gondivli Road, Purna, Bhiwandi-406125. INDIA

CALL US:- +91-8169813211 / 8169820763

EMAIL US:- info@pneuconveyors.com exports@pneuconveyors.com