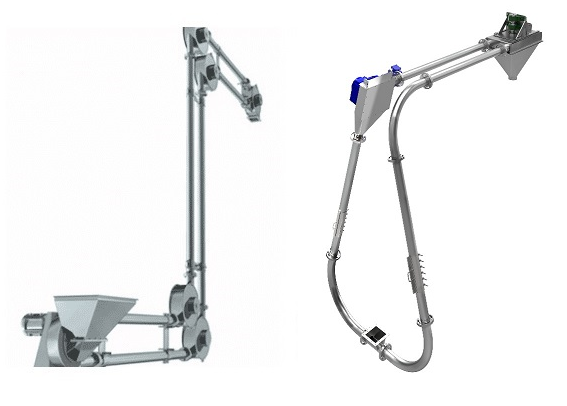

Tube chain conveyor design – Tubular chain conveyors are a type of mechanical conveying system that are designed to transport powders, granules, flakes, and other bulk materials in a sealed tube. The conveyor chain is made up of discs or tubes that are connected by flexible chains, and the material is moved along the conveyor by the motion of the chain.

The following are the key design considerations for a Tube chain conveyor design:

- Material properties: The first step in designing a tubular chain conveyor is to determine the properties of the material being conveyed, such as its bulk density, particle size distribution, flowability, and abrasiveness. These properties will determine the size and shape of the conveyor, the chain speed, and the type of chain that is used.

- Tube diameter and layout: The diameter of the tube will depend on the material properties and the desired conveying capacity. The tube layout should be designed to minimize friction and pressure drop, and to ensure that the material is evenly distributed along the length of the conveyor.

- Chain design: The chain must be designed to withstand the forces of the material being conveyed, as well as the tension and bending forces of the conveyor system. Chain selection will depend on the material properties and the desired conveying capacity.

- Drive system: The drive system must be designed to provide the necessary power to move the material along the conveyor at the desired speed. This may involve the use of a motor, gearbox, and chain drive.

- Sealing: Tubular chain conveyors are designed to be completely sealed, which means that the system must be designed with appropriate sealing mechanisms to prevent material leakage and ensure a clean and hygienic conveying environment.

- Maintenance and accessibility: The design should allow for easy access to all components for cleaning, maintenance, and repairs.

Overall, the design of a tubular chain conveyor should be tailored to the specific material being conveyed, the desired conveying capacity, and the operating environment. A well-designed system will provide reliable and efficient material handling, while minimizing downtime and maintenance requirements.